It seems that every time I turn around and try to get back on track with posting about my projects something new happens that sidetracks that goal. Unfortunately this past month and a half or so has been something of the same. The good news out of all of this though is that I now have a full time job which will be funding some of my projects a whole lot better than my previous unemployed state did.

One of the big things that has happened in the last month is that I have purchased a new power supply. This power supply is from Mastech/Volteq and is capable of 30 Volts and 10 Amps. I have a lot of plans for this supply and will do reviews on it as I cover various projects. To give you an idea I’d like to try out some aluminum anodizing, I plan on using it to dial in power for a cutting laser I’d like to design, and as you can imagine I will use it for various other microcontroller related projects. Keep an eye out for these projects and thoughts about how the power supply performs. So far I’ve used it for a few microcontrollers and it has been rock solid.

One of the big things that has happened in the last month is that I have purchased a new power supply. This power supply is from Mastech/Volteq and is capable of 30 Volts and 10 Amps. I have a lot of plans for this supply and will do reviews on it as I cover various projects. To give you an idea I’d like to try out some aluminum anodizing, I plan on using it to dial in power for a cutting laser I’d like to design, and as you can imagine I will use it for various other microcontroller related projects. Keep an eye out for these projects and thoughts about how the power supply performs. So far I’ve used it for a few microcontrollers and it has been rock solid.

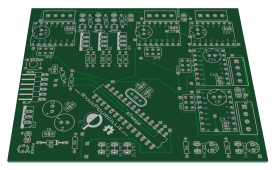

Lastly and most exciting to me is that I have finally completed my ShapeOko CNC build. Things were on and off as I was missing some parts and had a few issues along the way, but Edward, the creator of ShapeOko, was awesome all along the way and thanks to him I am up and cutting. So far I’ve cut a few bat symbols from plywood to dial things in and now I’m looking to move forward with cutting more complicated things as well as other materials. In classic fashion I’m also already looking into upgrades. I know it took me longer than it should have to put this standard kit together, but I’m already thinking a bigger work area is going to be necessary now that I have experienced true CNC power. So things I’m considering doing are: building a larger ShapeOko, building a laser circuit and a 3D printer extruder to use on my current ShapeOko, and continuing to look at various electronic setups while using the best features of each to create my own control board. These will probably be some long term projects, but like I mentioned once I started cutting things I can’t help wanting to go bigger and better.

Lastly and most exciting to me is that I have finally completed my ShapeOko CNC build. Things were on and off as I was missing some parts and had a few issues along the way, but Edward, the creator of ShapeOko, was awesome all along the way and thanks to him I am up and cutting. So far I’ve cut a few bat symbols from plywood to dial things in and now I’m looking to move forward with cutting more complicated things as well as other materials. In classic fashion I’m also already looking into upgrades. I know it took me longer than it should have to put this standard kit together, but I’m already thinking a bigger work area is going to be necessary now that I have experienced true CNC power. So things I’m considering doing are: building a larger ShapeOko, building a laser circuit and a 3D printer extruder to use on my current ShapeOko, and continuing to look at various electronic setups while using the best features of each to create my own control board. These will probably be some long term projects, but like I mentioned once I started cutting things I can’t help wanting to go bigger and better.

February and the beginning of March have been rather busy and I haven’t had a chance to post much to the site. That being said I have still been working on some things to improve it. Some of you may have already noticed, but I’ve added a bit to my logo and changed the site header. That’s where things started. I felt the logo before was too plain and wanted to add to it and I felt like the site header could be better as well. I don’t know that either change is perfect yet, but I like them better thus far. I’ll roll out a few more things relating to this logo change and a new video introduction I’m working on in the near future so keep an eye out.

February and the beginning of March have been rather busy and I haven’t had a chance to post much to the site. That being said I have still been working on some things to improve it. Some of you may have already noticed, but I’ve added a bit to my logo and changed the site header. That’s where things started. I felt the logo before was too plain and wanted to add to it and I felt like the site header could be better as well. I don’t know that either change is perfect yet, but I like them better thus far. I’ll roll out a few more things relating to this logo change and a new video introduction I’m working on in the near future so keep an eye out.

You must be logged in to post a comment.